8

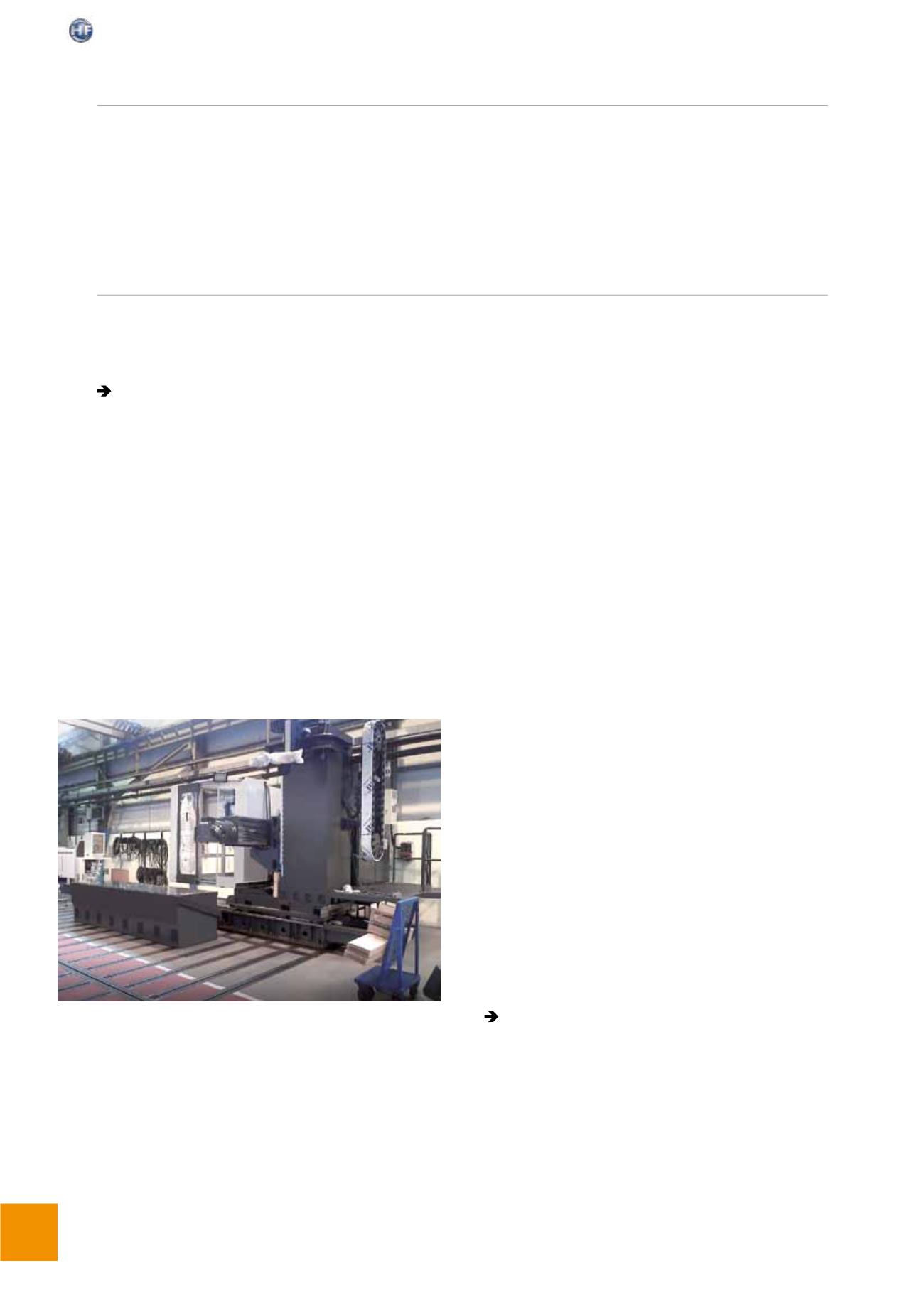

New bed-type milling machine commissioned

Farrel, Rochdale, Great Britain

Preparations for the latest member to join the machinery

at Farrel Ltd. in Rochdale took quite some time, but the

moment eventually came in October: the new Correa 7 M,

a milling machine with a travelling column, manufactured

by the Spanish company Correanayak, finally entered

service. In the months leading up to that point, the

foundations were prepared for the newcomer: to this

end, a two-and-a-half-metre-deep hole was dug, during

which an interesting artefact was unearthed: the team

found the remnants of an old brick chimney which had

evidently once stood here. The concrete and steel

foundations were then cast and the machine was mount‑

ed on them once they had set.

Those responsible for choosing a new machine espe-

cially focused on the functionality and the component

geometry, but they also paid close attention to health

and safety aspects. It is the first bed-type milling machine

of its kind at Farrel Ltd. to feature two workspaces,

guaranteeing completely safe operation according to

the manufacturer from the northern Spanish city of Bur-

gos. The machine was transported from Spain to Wales

on two large trucks and a team set to work on assem-

bling it as soon as it was unloaded. The bed of the

milling machine was in the correct position after just

two days and the mortar could then be applied. Once

the bed had been assembled, the travelling column

was immediately installed. John Saxon from the ma-

chinery department and engineer Jonathan Gudgeon

spent a week in Spain beforehand to acquaint them-

selves with the finer details of operating the machine. In

future, it will be just as possible to drill, groove and mill

as it will be to turn profiles. From a technical perspective,

it is a bed-type milling machine with a rotary table – the

travelling column is seven metres long, 1.25 metres

deep and two metres high. One special feature of the

machine is its universal milling head which can move in

five directions. The universal milling head is capable of

4,000 revolutions per minute with an output of up to 24 kW.

The machine has two workspaces, a rotary table and a

tailstock. The coolant is added at a pressure of up to 32 bar

and 40 milling and drilling bits are changed automati‑

cally.

The machine was commissioned in September and

began production in October. It replaces the old Mandelli

machine and will relieve the burden on the existing

Butler. The colleagues in Rochdale cannot wait to see

all the things the newcomer can do and will use it to try

out some new applications!

Workout after work:

Employees’ fitness studio opens

Harburg-Freudenberger, Freudenberg, Germany

An increasing number of firms are taking an interest in

preventive health care measures for their employees

and setting up company sports programmes. Fully in

keepingwith this trend, Harburg-Freudenberger Maschinen‑

bau GmbH has now opened ‘STARK by HF MIXING

GROUP’ in Freudenberg, a modern fitness studio for its

employees.

MIXING

TOGETHER

| MIXING news

MIXING news

What is new at the HF MIXING GROUP locations around

the world? We report on what has been happening.

The new ‘all-rounder’ in Rochdale: the Correa 7 M milling machine.