Every new rubber compound and every new mixture component not only entails new properties for the end product, but also significantly alters the process be- haviour of the material during mixing and further processing. Silica compounds have been tried and trusted in the manufacture of car tyres for a number of years, because many relevant factors, such as noise emissions, rolling resistance and braking distance can be positively influenced by their use. For the production of the basic rubber material, however, the use of silica additives creates completely new challenges in relation to the mixing process and how the finished rubber compound is handled, especially when it comes to master batches.

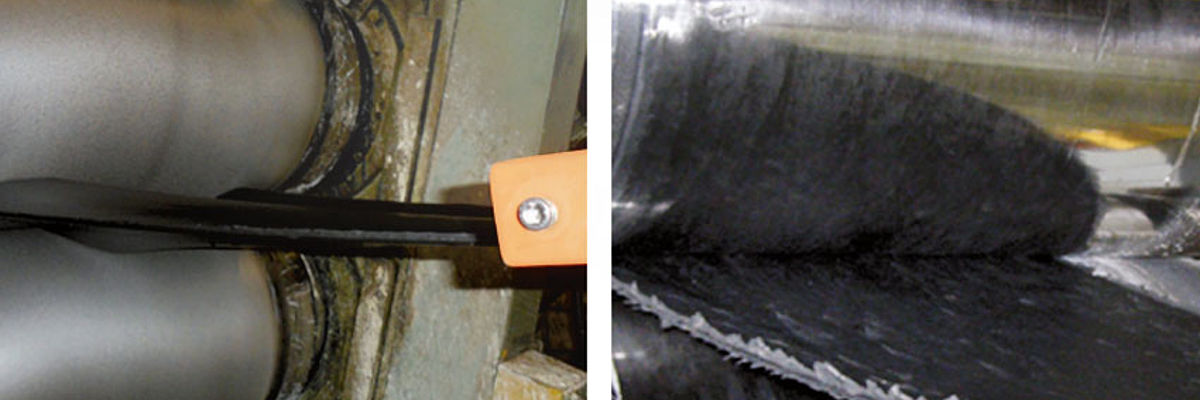

Complex chemical reactions between the individual components and additives take place during the mixing process. When silicic acid is used, this is grafted onto the filler surface during mixing by means of a compound such as silane and later (in the heating press) chemically bonded to the polymer. The properties of the finished tyre can be improved considerably as a result of this process. However, silica compounds prove to be highly adhesive on the mixing line. This means that the rubber compound ‘sticks’ more firmly to the inside of the mixing chamber, the discharge screws and the rollers on the roller die, which turn the master batch into a six- to eight-millimetre-thick coat that clings to the rolling mills and twin-screw discharge extruders.

The HF MIXING GROUP has come up with a solution to this problem in the form of ASMACool. Its combination of roller design and surface, and controlled roller cooling is new and totally unique. ASMACool stands for Anti-Sticking MAximum Cooling. The HF engineers discovered that merely controlling the temperature of the discharge rollers can only counteract the sticking effect to a limited extent, so the classic dilemma of wishing to have the cake and eat it had to be solved in a different way. Accordingly, in a series of tests carried out at HF, the interaction between the rubber mass and the roller surface was examined in-depth. The developers discovered that the gases released, especially by certain silica compounds, have a highly corrosive effect on the roller surface. As a result, the surface becomes rougher, which in turn helps the medium – in this case the compound – to stick to it.

Their answer was to use a special process to produce high-strength, corrosion-resistant hard plating for the rollers, which suppresses the aforementioned phenom‑ e‑non to the greatest possible extent. The armour plating on an ASMACool roller is so hard that not even a foreign body such as a hammer or spanner can damage it. A further advantage is the fact that the rollers can be repaired on-site using build-up welding. This special anti-stick coating is currently only offered by HF. Virtually all the commonly used rolling mills and roller dies supplied by the HF MIXING GROUP can now be fitted with ASMACool rollers. It is a unique selling point which offers customers in the tyre and rubber goods industry significantly higher discharge yields, while also improving the effectiveness of the mixing lines, minimising maintenance work and unplanned downtimes caused by jammed rollers and generally increasing process safety. This development was not only conceived with a focus on silica compounds, but primarily against the backdrop of the increasing number of new raw materials and chemical components that will define the future of tyre and rubber production.