A specialised solution is not always the best choice. There are applications for which one and the same mixer is intended to be used for various compounds and various mixing applications. This is the case, for instance, in labora‑ tories or industrial applications where the batch sizes don’t use a special machine to its full capacity. The UMIX universal mixer series is the right answer for achieving excellent results when mixing low- to high-viscosity media in varying compounds with minimal investment. The HF MIXING GROUP took over this product series from the Stuttgart-based Coperion GmbH in summer 2013.

‘The UMIX series perfectly enhances our product range for those customers who produce small to medium-sized quantities and have to manufacture varying compounds on one machine at reasonable investment costs,’

says Ulrich Gerhards, UMIX product group manager, welcoming the expanded product range.

With capacities ranging from 0.25 to 4,300 litres, the series covers a broad spectrum of possible applications. Besides pure mixing and kneading, the UMIX series can handle simultaneous processes such as moistening, plasticising, dispersing, homogenising, melting, cooling, degassing, evaporation, dissolving and reacting during the mixing process.

The function of the machine is based on a twin blade principle with two tangentially counter-rotating blades which, in interaction with the trough wall, produce an optimal shear rate in the mixture, thereby ensuring homoge‑ neous mixing results. The temperature of trough and/or blades can be adjusted on many of the model sizes, which is just as interesting for laboratory and test applications as for temperature-critical mixing processes in industrial production.

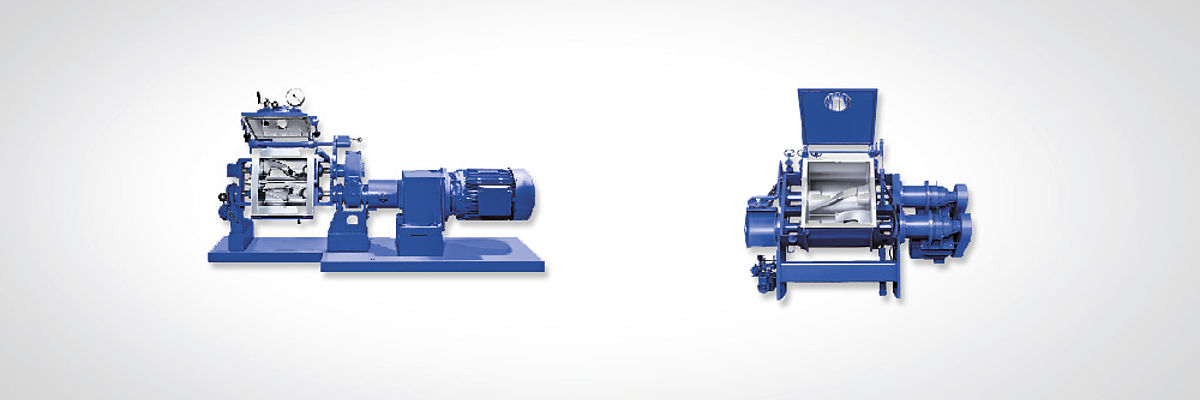

The UMIX is available as a compact version for laboratories and a powerful version for industry. The product can either be discharged by tilting the trough or – on very small machines – by simply removing the trough. The option to empty the machine via discharge screws or bottom outlets is available on many of the model sizes. On request, the models can be supplied with additional components fitted, such as nozzles for pelletising or profile extrusion. Overall, the UMIX series has a range of impressive features, including its compact design, wide range of mixing applications, convenient operation, safe process management and various configuration options with respect to performance, functions and capacity. (Further information can be found at: www.hf-group.com/umix).

Additional features:

- Two product lines for production and laboratory

- Product extraction by tilting, discharge screw or bottom valve – to be chosen*

- Multiple machine sizes from 0.25 to 4,300 l net volume

- Process control with temperature-adjustable troughs and blades

- Blade geometry, material selection and drive design adapted to customer-specific process requirements*

- Profile extrusion via nozzle and pelletising possible for discharge screw versions*

* depending on version and/or size